Stainless Steel Paint for Galvanized Steel, Tin, Aluminum Concrete Superlife-316 DTMR

SuperLife-316™ is a low VOC USDA accepted gray paint with 316 stainless steel additive for most metals including galvanized steel, tin, aluminum and even concrete. SupeLife 316 also has the ability to adhere to metal surfaces where slight oil and grease contamination is present.

- Description

- Request Best Price - Information

- SuperLife-316 DTMR™ Physical Properties

- Additional information

Stainless Steel Paint for Galvanized Steel, Tin, Aluminum and Concrete

Superlife-316 is a single component, water-based acrylic emulsion coating pigmented with alloy 316 stainless steel flake. It is non-flammable, low VOC, and offers superb exterior durability. It has excellent adhesion and abrasion resistance.

Superlife-316 DTMR, a liquid stainless steel coating that can be used as a direct to metal primer and/or topcoat on properly prepared steel, galvanized steel, tin, aluminum, and concrete. It can also be used as a topcoat over primed steel surfaces and most previously painted surfaces in corrosive atmospheres.

Superlife-316 DTMR can be used directly to the metal in an interior, dry applications. When used in exterior or wet applications a primer is required. Superlife-316 DTMR incorporates stainless steel with high quality; fast dry, flexible water-based acrylic resin to provide outstanding exterior durability. It is FDA and USDA accepted and is available in metallic gray and other metallic colors. VOC compliant.

Burke Industrial Coatings has manufactured water base stainless steel filled coatings since 1963. Our largest selling product at this writing is our Superlife-316 DTMR, which is used extensively by OEM’s in the production of packaging and processing equipment. Superlife-316 DTMR is a single component, stainless steel filled, fast dry coating. It can be used directly to the metal in applications where the product painted is going into a non-critical or dry atmosphere. If used in severe duty applications, we recommend the use of a primer before coating with DTMR. Superlife-316 DTMR has the ability to bite through some light grease or oil contaminants that may be on the surface, but, as always, we recommend a thorough cleaning of the parts to be painted.

DTMR is an offshoot of our Superlife-316® which has been used in industrial applications since 1965. The more we sold to OEM customers, the more the need for faster drying, quicker curing product became evident. OEM customers were looking for a water base, stainless steel coating that would withstand assembly or packing for shipment within minutes after painting. Since Superlife-316® is a fairly slow drying product and takes up to 10 days to fully cure, we began to look for component ingredients that would still give us the excellent exterior durability of Superlife-316® but with a faster dry and quick cure. The resultant product, DTMR, dries to touch in 15 to 20 minutes and reaches 90% of its full cure within 8 to 12 hours. Accelerated weathering tests indicate that the DTMR will also give exterior performance equal to or better than the original Superlife-316.

SuperLife-316™ Low VOC Gray paint with stainless steel additives has the ability to adhere to metal surfaces with a slight contamination of oils or greases.

SuperLife-316™ Cured Appearance: Low sheen metallic gray

Recommended Primers for SuperLife-316™: PrimeLock Low VOC Gray, Prime Solution 5250 Red/5253 Gray, Steel Plus Epoxy Primer

How to Apply Gray Stainless Steel for Galvanized Steel, Tin, Aluminum and Concrete:

Quality paint jobs occur with quality preparation, products, and application. Quality preparation includes cleaning the surface to be painted to remove all contaminants by washing with BC4000 or other suitable cleaners. Thoroughly cured old coatings may require scuff sanding for maximum adhesion.

Equipment Recommended Superlife 316 Low VOC Stainless Steel Low Sheen Gray Paint:

Filter: Use 50 mesh stainless steel screen or nylon bag when needed

Brush On: Use a quality synthetic bristle brush

Roller Application: Use quality roller cover

Air Atomized Sprayer: Follow equipment manufacturers nozzle and needle selection recommendation for use with heavy latex paints. Spray at 45-60 psi.

Airless Spaying: 2000-2500 psi with 0.017 to 0.021 tip.

Hot Spraying: 100-120F

Thinning SuperLife-316™ Stainless Steel Low Sheen Paint:

Rolling / Brush: Use clean water. Thinning is normally not required. Use 5%-10% if needed (approximately 1/2 pint per gallon)

Air Atomizer Spray: Use clean water. Thinning is normally not required. Use 5%-10% if needed (approximately 1/2 pint per gallon)

Airless Sprayer: Use clean water. Thinning is normally not required. Use 5%-10% if needed (approximately 1/2 pint per gallon)

Cleanup: Soap and Water

Properties of SuperLife-316™ Gray Metallic Stainless Steel Additive Paint:

WEIGHT PER GALLON 9.71 Lbs

SOLIDS BY WEIGHT 43.0%

SOLIDS BY VOLUME 33.4%

Recommended DFT 2.5 mils

WFT TO ACHIEVE DFT 7.5 mils

THEORETICAL COVERAGE @1 MIL DFT 533 sq. Ft./gal

ACTUAL COVERAGE AT RECOMMENDED DFT 213 sq. Ft./gal

DRY TIME @77F AND 50% HUMIDITY

Tack Free: 30-45 minutes

Handle: 1 hour

Recoat: 1-2 hours

Full Cure: 7 days (can be accelerated)

HEAT RESISTANCE WHEN FULLY CURED 400F / 200C

Shelf-life 2 year[/vc_column_text][vc_column_text]

Safety Information for SUPERLIFE-316™ Stainless Steel Additive Coating:

VOC: 100 g/L or .84 Lbs/Gal

Flash Point: N/A

USDA: Authorized by USDA for use in federally inspected meat and poultry plants.

Do not take internally. Close containers tightly after use and keep upright. In case of spillage, absorb and dispose of in accordance with locally applicable regulations. California Prop 65 Warning: Detectable amounts of chemicals known to the State of California to cause cancer, birth defects or other reproductive harm, may be found in this product or its vapor. For specific information refer to the Safety Data Sheet(SDS).

*** FOR INDUSTRIAL USE ONLY. KEEP OUT OF REACH OF CHILDREN. ***

SUPERLIFE-316™ Gray Metalic Stainless Steel Paint Ordering Information:

| Product Number | Size | Wt./Case | Case Quantity |

| 10-1418-04 | Quart | 27 | 6 |

| 10-1418-01 | Gallon | 40 | 4 |

| 10-1418-05 | 5 Gallon | 53 | 1 |

| 10-1418-55 | 55 Gallon | 585 | 1 |

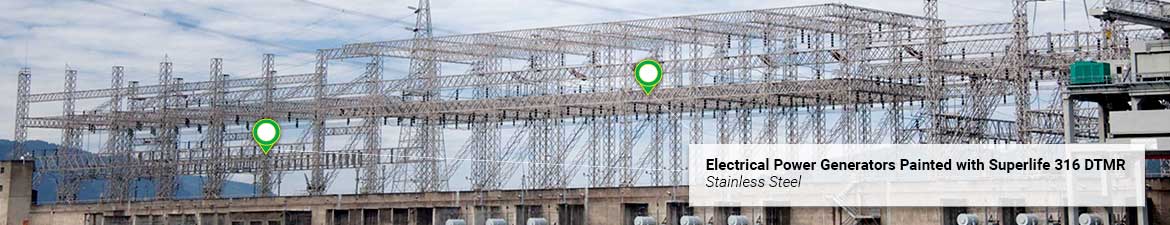

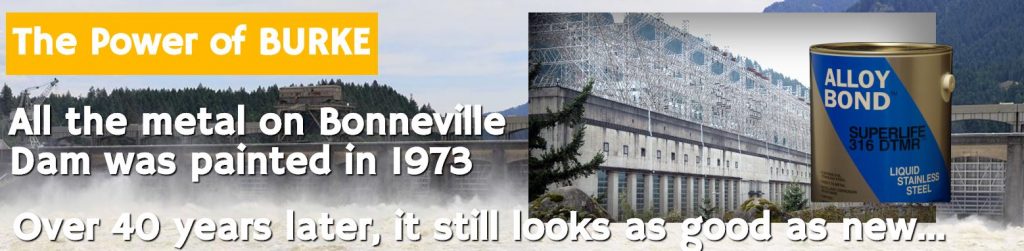

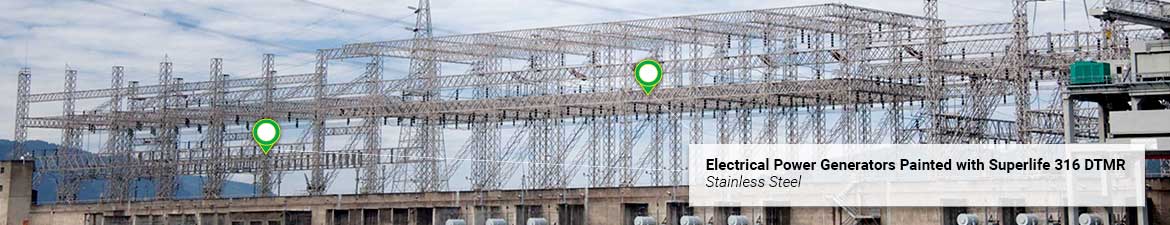

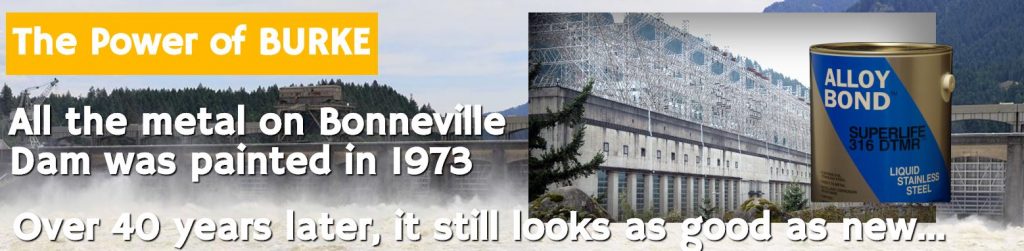

SuperLife 316 DTMR Stainless Steel Bonneville Dam Painted

Ready to Use Fast Drying Metal Stainless Steel Urethane Coating SuperLife-316U Superlife-316U is ready to use urethane coating, pigmented with 316 stainless steel flake making it a fast dry and good color retention coating. Ideal for equipment and areas where a minimum of downtime is desired with long-term corrosion protection and good abrasion resistance. |

WEIGHT PER GALLON 9.71 Lbs

SOLIDS BY WEIGHT 43.0%

SOLIDS BY VOLUME 33.4%

RECOMMENDED DFT 2.5 mils

WFT TO ACHIEVE DFT 7.5 mils

THEORETICAL COVERAGE @1 MIL DFT 533 sq. ft./gal

ACTUAL COVERAGE AT RECOMMENDED DFT 213 sq. ft./gal

DRY TIME @77F AND 50% HUMIDITY

Tack Free: 30-45 minutes

Handle: 1 hour

Recoat: 1-2 hours

Full Cure: 7 days (can be accelerated)

HEAT RESISTANCE WHEN FULLY CURED 400F / 200C

SHELF-LIFE 2 year

Additional information

| Size | Quart, Gallon, 5 Gallon, 55 Gallon |

|---|

Stainless Steel Paint for Galvanized Steel, Tin, Aluminum and Concrete

Superlife-316 is a single component, water-based acrylic emulsion coating pigmented with alloy 316 stainless steel flake. It is non-flammable, low VOC, and offers superb exterior durability. It has excellent adhesion and abrasion resistance.

Superlife-316 DTMR, a liquid stainless steel coating that can be used as a direct to metal primer and/or topcoat on properly prepared steel, galvanized steel, tin, aluminum, and concrete. It can also be used as a topcoat over primed steel surfaces and most previously painted surfaces in corrosive atmospheres.

Superlife-316 DTMR can be used directly to the metal in an interior, dry applications. When used in exterior or wet applications a primer is required. Superlife-316 DTMR incorporates stainless steel with high quality; fast dry, flexible water-based acrylic resin to provide outstanding exterior durability. It is FDA and USDA accepted and is available in metallic gray and other metallic colors. VOC compliant.

Burke Industrial Coatings has manufactured water base stainless steel filled coatings since 1963. Our largest selling product at this writing is our Superlife-316 DTMR, which is used extensively by OEM’s in the production of packaging and processing equipment. Superlife-316 DTMR is a single component, stainless steel filled, fast dry coating. It can be used directly to the metal in applications where the product painted is going into a non-critical or dry atmosphere. If used in severe duty applications, we recommend the use of a primer before coating with DTMR. Superlife-316 DTMR has the ability to bite through some light grease or oil contaminants that may be on the surface, but, as always, we recommend a thorough cleaning of the parts to be painted.

DTMR is an offshoot of our Superlife-316® which has been used in industrial applications since 1965. The more we sold to OEM customers, the more the need for faster drying, quicker curing product became evident. OEM customers were looking for a water base, stainless steel coating that would withstand assembly or packing for shipment within minutes after painting. Since Superlife-316® is a fairly slow drying product and takes up to 10 days to fully cure, we began to look for component ingredients that would still give us the excellent exterior durability of Superlife-316® but with a faster dry and quick cure. The resultant product, DTMR, dries to touch in 15 to 20 minutes and reaches 90% of its full cure within 8 to 12 hours. Accelerated weathering tests indicate that the DTMR will also give exterior performance equal to or better than the original Superlife-316.

SuperLife-316™ Low VOC Gray paint with stainless steel additives has the ability to adhere to metal surfaces with a slight contamination of oils or greases.

SuperLife-316™ Cured Appearance: Low sheen metallic gray

Recommended Primers for SuperLife-316™: PrimeLock Low VOC Gray, Prime Solution 5250 Red/5253 Gray, Steel Plus Epoxy Primer

How to Apply Gray Stainless Steel for Galvanized Steel, Tin, Aluminum and Concrete:

Quality paint jobs occur with quality preparation, products, and application. Quality preparation includes cleaning the surface to be painted to remove all contaminants by washing with BC4000 or other suitable cleaners. Thoroughly cured old coatings may require scuff sanding for maximum adhesion.

Equipment Recommended Superlife 316 Low VOC Stainless Steel Low Sheen Gray Paint:

Filter: Use 50 mesh stainless steel screen or nylon bag when needed

Brush On: Use a quality synthetic bristle brush

Roller Application: Use quality roller cover

Air Atomized Sprayer: Follow equipment manufacturers nozzle and needle selection recommendation for use with heavy latex paints. Spray at 45-60 psi.

Airless Spaying: 2000-2500 psi with 0.017 to 0.021 tip.

Hot Spraying: 100-120F

Thinning SuperLife-316™ Stainless Steel Low Sheen Paint:

Rolling / Brush: Use clean water. Thinning is normally not required. Use 5%-10% if needed (approximately 1/2 pint per gallon)

Air Atomizer Spray: Use clean water. Thinning is normally not required. Use 5%-10% if needed (approximately 1/2 pint per gallon)

Airless Sprayer: Use clean water. Thinning is normally not required. Use 5%-10% if needed (approximately 1/2 pint per gallon)

Cleanup: Soap and Water

Properties of SuperLife-316™ Gray Metallic Stainless Steel Additive Paint:

WEIGHT PER GALLON 9.71 Lbs

SOLIDS BY WEIGHT 43.0%

SOLIDS BY VOLUME 33.4%

Recommended DFT 2.5 mils

WFT TO ACHIEVE DFT 7.5 mils

THEORETICAL COVERAGE @1 MIL DFT 533 sq. Ft./gal

ACTUAL COVERAGE AT RECOMMENDED DFT 213 sq. Ft./gal

DRY TIME @77F AND 50% HUMIDITY

Tack Free: 30-45 minutes

Handle: 1 hour

Recoat: 1-2 hours

Full Cure: 7 days (can be accelerated)

HEAT RESISTANCE WHEN FULLY CURED 400F / 200C

Shelf-life 2 year[/vc_column_text][vc_column_text]

Safety Information for SUPERLIFE-316™ Stainless Steel Additive Coating:

VOC: 100 g/L or .84 Lbs/Gal

Flash Point: N/A

USDA: Authorized by USDA for use in federally inspected meat and poultry plants.

Do not take internally. Close containers tightly after use and keep upright. In case of spillage, absorb and dispose of in accordance with locally applicable regulations. California Prop 65 Warning: Detectable amounts of chemicals known to the State of California to cause cancer, birth defects or other reproductive harm, may be found in this product or its vapor. For specific information refer to the Safety Data Sheet(SDS).

*** FOR INDUSTRIAL USE ONLY. KEEP OUT OF REACH OF CHILDREN. ***

SUPERLIFE-316™ Gray Metalic Stainless Steel Paint Ordering Information:

| Product Number | Size | Wt./Case | Case Quantity |

| 10-1418-04 | Quart | 27 | 6 |

| 10-1418-01 | Gallon | 40 | 4 |

| 10-1418-05 | 5 Gallon | 53 | 1 |

| 10-1418-55 | 55 Gallon | 585 | 1 |

SuperLife 316 DTMR Stainless Steel Bonneville Dam Painted